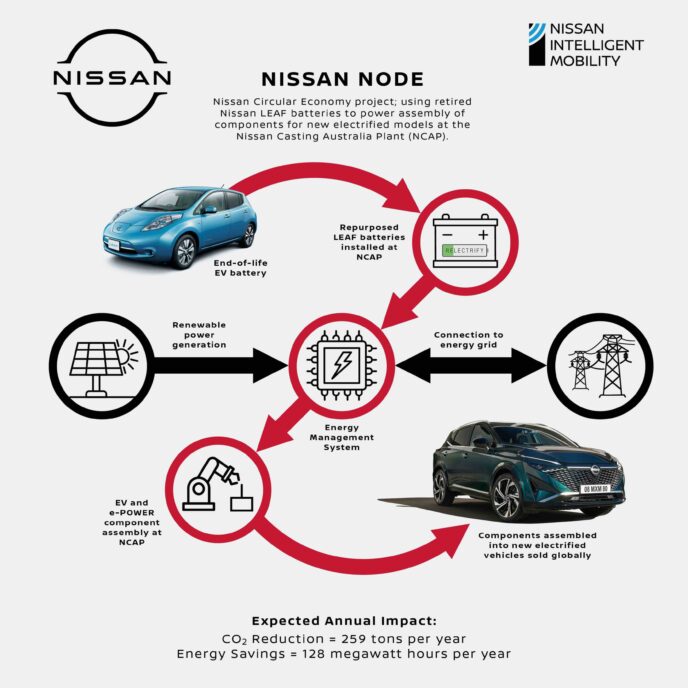

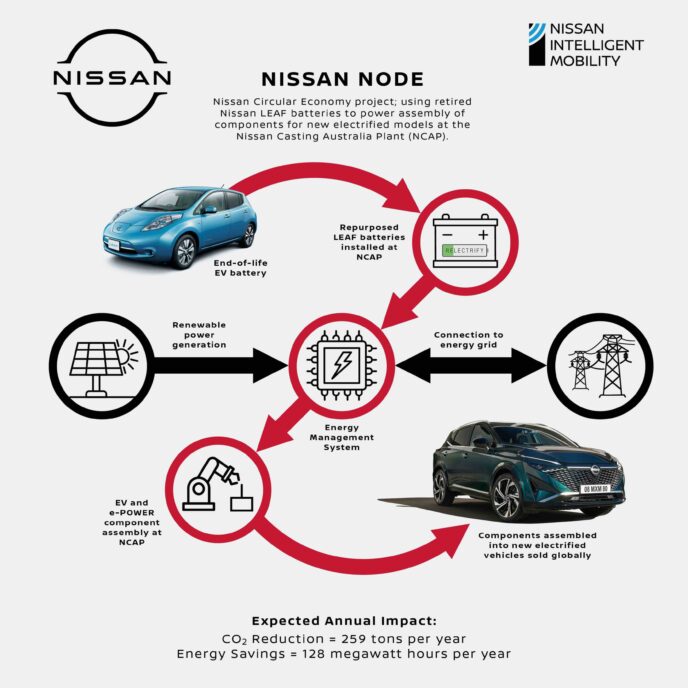

nissan Australia has unveiled a circular economy initiative that will see end-of-life nissan Leaf batteries repurposed to power part of its Dandenong production facility, marking a significant step in the company’s sustainability strategy.

The project, called nissan Node, installs a new solar array and a battery-energy storage system made up of nine repurposed first-generation Leaf batteries at the nissan Casting Australia Plant (NCAP). The stored renewable energy will support manufacturing operations and supply newly installed EV chargers used by staff.

nissan estimates the system will cut NCAP’s annual CO2 emissions by 259 tonnes and save 128 megawatt-hours of energy each year.

“This isn’t just a hugely exciting project, but an important step into the future for end-of-life EV batteries,” nissan Oceania managing director Andrew Humberstone says.

“As an early pioneer of the electric vehicle both globally and locally, we can also demonstrate leadership in second-life battery initiatives. I’m proud that this solution is every bit as innovative as the launch of not only the Leaf but the recently introduced ARIYA.”

Established in 1982, NCAP is one of nissan’s key global manufacturing hubs. More than half of its operations now focus on producing high-pressure aluminium castings for nissan’s electric and hybrid vehicles sold worldwide. Every nissan Leaf and next-generation e-POWER powertrain includes components made at the Dandenong plant.

Humberstone says the new project reflects the ongoing ingenuity of the Australian operation.

“This is another great, innovative idea from the nissan Casting Australia Plant team that creates a sustainable solution for nissan’s end-of-life electric vehicle batteries,” he says.

“This nissan Node Project perfectly demonstrates the nissan way of thinking to ‘Challenge for the Future’. We are very proud of our NCAP team, which continues to innovate and improve to ensure our advanced manufacturing capability, not only for nissan but also for Australia.”

The initiative was delivered in partnership with Melbourne-based technology firm Relectrify, which developed the battery-management and inverter technology enabling second-life Leaf batteries to be repurposed effectively. Its ReVolve energy-storage system installed at NCAP is the first Commercial product built entirely from retired Leaf batteries.

“We are delighted to be working with nissan on this initiative, which positions Australian innovation at the forefront of the global transition towards both carbon neutrality and the Circular Economy,” Relectrify chief executive Jeff Renaud says.

nissan says the completion of the Node project is a key step on its wider carbon-neutrality journey as it expands its electrified portfolio, including the ARIYA and upcoming e-POWER-equipped models.

Automobile Magazine-AU