Volkswagen Commercial Vehicles saved 100,000 tonnes of CO2….

İLGİ ÇEKENLER

Strongest new bus and coach market since 2008 as zero emission uptake surges

New bus, coach and minibus market grows 10.4% in 2025, with 9,259 vehicles joining UK...

GWM UK delivers POER300 pick-up to NFU Scotland as affinity programme announced

NFU Scotland has added a GWM POER300 Ultra to its fleet, supplied by A F...

Volvo launches EX30 Black Edition with striking new look

Black Edition adds design enhancements to the popular compact SUV

Available across single and twin motor variants...

Introducing the Porsche 911 Carrera Cabriolet Reimagined by Singer

Singer’s latest services incorporate a state-of-the-art, 420BHP, naturally aspirated flat six, restored and developed by...

World’s first laser-engraved bonnet honours Middle East’s architectural heritage

First-ever laser-engraved Rolls-Royce bonnet: a technique five years in the making

One-of-one commission by Private Office...

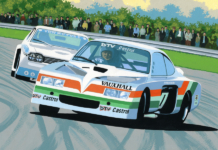

Castle Combe Circuit Renames Corners in Honour of Venue’s Pioneers

Castle Combe Circuit has announced the renaming of two corners of the 1.85-mile Wiltshire race...

Helix delivers EV technology for McMurtry Automotive

Helix partners with McMurtry Automotive to develop rear-wheel propulsion system for the record-breaking McMurtry Spéirling Pure Electric...

Barn stored 2015 Defender set for sale

An exceptional 2015 Land Rover Defender 90 Pick-Up with just one owner and 124 miles...

Extreme athlete aims for world record to help save children living with rare brain disease

Darren Hardy will pull a Land Rover 100km in 100 hours to raise £100,000 for...

50 Years of Castle Combe Circuit Ltd to be Celebrated at 2026 Autumn Classic

Wiltshire’s Castle Combe Circuit will celebrate the half centenary of Castle Combe Circuit Ltd at...

Honda launches the Dream Bigger Sales Event* with £1,000 bonus saving on hybrid models

Honda is encouraging more UK drivers to move into electrified motoring with the launch of...

Sporting Bears Motor Club raises £4 million for children’s charities

Sporting Bears is set to break the £4 million barrier with its fundraising activities, at...

Suzuki welcomes Murley Auto Ltd as new retail partner in Stratford-upon-Avon

Suzuki GB PLC has recently announced the appointment of Murley Auto Ltd as a new...