Challenges and Opportunities Ahead for Batteries

İLGİ ÇEKENLER

Çok Okunanlar

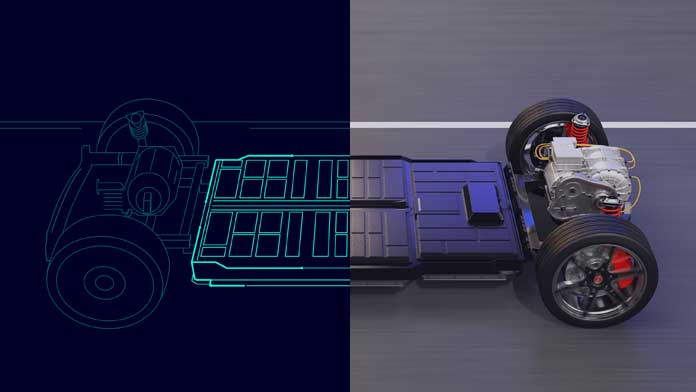

Accelerate product development

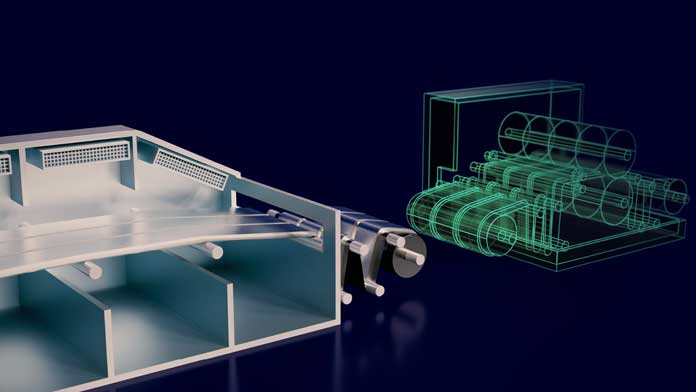

Maximize production

The problem boiled down to quality prediction during manufacturing. Leveraging Siemens battery manufacturing solutions coupled with battery intelligence software provider, Voltaiq, the customer was able to identify early signals of failure within the first hours of formation. By automating this validation process, informed by upstream data from process and measurement data, a causal link was found between the failed cells and the slitting blade replacement during production. AI in the form of machine learning was used as well, to set up predictive maintenance procedures for blade replacement. By giving context to the data with the cDT and AI, this manufacturer was able to avoid the 2 percent capacity reduction and apply the same methodology across other critical-to-quality issues for over a 10 percent aggregate yield improvement.

About the Author:

Alonso’s pride: “Now I can finally drive a Newey car”

The new Aston...

Here is the Aston Martin AMR26 – PHOTO

The veils are...

Engine case, FIA admits: “Some increase the compression ratio when hot”

The (first) controversy...

Cadillac, Perez: “We learn more and more about the car’s capabilities”

Cadillac, the new...

McLaren, Stella’s trust: “Team, drivers, engine, we have the best package”

The new McLaren...

Piastri: “I feel stronger than ever”

Piastri launches the...

Mercedes engines case, Zak Brown: “It can be fine, it’s the usual political games”

The Mercedes engine...

McLaren, here is the livery of the MCL40 – GALLERY

McLaren presents the...

McLaren presents the MCL40 livery: off at 4pm – LIVE

McLaren, here is...

Super Bowl and F1, not just Cadillac: Hamilton and Leclerc also present

The Super Bowl...

Piastri and his two ‘Achilles heel’ circuits from last season

Missed opportunity Following...

Goodbye to Enrico Benzing

There was a...

Entry into Alpine: Horner discusses with an American fund, former McLaren shareholder

Horner coming back?...